CALIBRATION

The built-in redundancy of the physics prototype calibration and readout system

allows several different monitoring concepts to be applied and cross-checked.

The calibration capabilities of new developed photodetectors (MGPDs, see below)

can be of manifold use, from production quality control to commissioning

diagnostics, linearity correction and temperature monitoring.

Novel photodetector MGPD and its calibration

The scintillator based hadron calorimeter relies on the use of novel Multi-Pixel

Geiger mode silicon Photo-Detectors (MGPDs). The MGPD (often called Silicon Photomultiplier

- SiPM)

is a pixilated avalanche photo-diode operated in limited Geiger mode (see figure on the

left). The detector surface of lxl mm² is divided into 1156 pixels. We gained

experience with this photodetector building small test calorimeter MiniCal with

about 100 MGPD channels [see MiniCal].

The scintillator based hadron calorimeter relies on the use of novel Multi-Pixel

Geiger mode silicon Photo-Detectors (MGPDs). The MGPD (often called Silicon Photomultiplier

- SiPM)

is a pixilated avalanche photo-diode operated in limited Geiger mode (see figure on the

left). The detector surface of lxl mm² is divided into 1156 pixels. We gained

experience with this photodetector building small test calorimeter MiniCal with

about 100 MGPD channels [see MiniCal].

The analog output is obtained by adding the response of all pixels fired as

independent digital counters. The MGPD are operated at 2-3 volts above breakdown

voltage (typically at 55 V). By being the internal pixel capacitance

Cpixel of typically 50 fF the charge collected for

one photo-electron signal is ~160 fC (or ~106 electrons).

The MGPD offers a very fast response with a typical rise time of the

order of a nanosecond. The fall time of the signal depends on the pixel

quenching resistor and can be tuned to the needs of the experimental

application (typical values are between 2-150 ns). The dynamic range

is determined by the finite number of pixels and is ~200 pC.

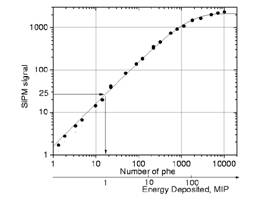

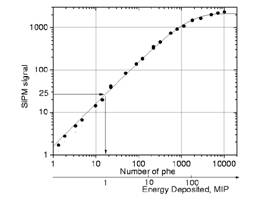

MGPDs have virtues as well as drawbacks. The left figure above displays

the MGPD signal as a function of the number of photoelectrons released from the

photocathode. The signal becomes saturated at high light intensities as a

result of finite number of pixels. At low light intensities one can distinguish

individual photoelectrons on the photocathode equally spaced. This allows

obtain the gain. MGPDs with their high intrinsic gain are sensitive to

temperature and bias voltage fluctuations. The typical values are -1.7% per

temperature increase of 1°C and 2.5% per 0.1V change of bias voltage.

Therefore, calibration and monitoring systems (see next section) are of central

importance. Their layout has important consequences for mechanical structures

and electronics specifications. Careful evaluation of present running

experience and characterization of different hardware solutions must enter into

final conceptual design choices, and it may be appropriate to pursue more than

one option during the next R&D cycle.

Calibration and Monitoring Board

The task of calibration is to obtain gain and measure the nonlinearity

of each MGPD. The aim of monitoring is to record response of a MGPD on long

time scale and provide correction factors for gain which changes due to the

temperature, bias voltage fluctuations and also due to non predictable

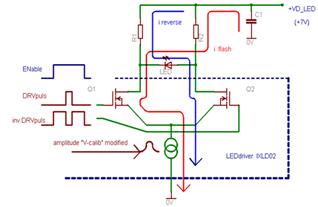

situations. The Calibration and Monitoring Board (CMB) provides short steered

pulses for UV LEDs and the light is carried by clear fibers to each

scintillator tile.

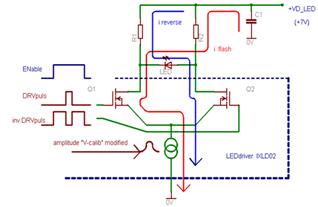

The pulses are provided by a LED driver which has fast rise and fall

edges of the rectangular signal of ~ 10 ns width. The amplitude can be tuned

from zero to 6 V. Each LED is monitored by a PIN diode. The corresponding light

intensity in the tile changes from several photons to the equivalent of light

produced by the passage of up to 100 minimum ionizing particles. The low

intensity light is used to observe single photoelectron peaks in the MGPD which

are equally spaced and allow obtaining gain of each MGPD. With a sweeping from

low up to high intensities the saturation curve of a MGPD can be measured.

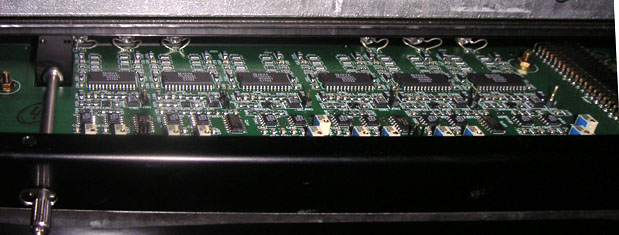

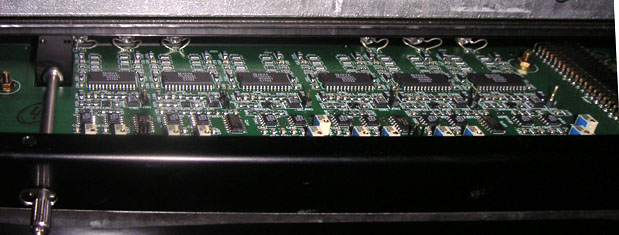

Each detection plane with 216 MGPDs has on a side one CMB which is

divided to two printed boards. The upper one is shown in the figure with

circuits for 6 LEDs. The LED driver is controlled by DAQ via CAN bus which

allows to control parameters like enabling, pulse width and amplitude. The

board contains also the temperature readout from sensors connected to the

photodetectors.

Operational experience and calibration

The HCAL was assembled and commissioned at DESY, where also an initial

calibration of the active layers was obtained in the electron test beam. In

2006, together with ECAL and TCMT, the stack with 23 instrumented layers was

exposed to electron and hadron beams of 6-45 GeV and 6-120 GeV, respectively, in

the H6 beam line at the CERN SPS. In addition high intensity muon beams were

available for calibration.

All calorimeter cells have been calibrated with muons. The

minimum ionizing particle (MIP) signal AMIP

is used as a scale for the deposited energy and to set the noise suppression

threshold of ½ MIP, which yields a MIP hit efficiency of about 95%. The

noise hit occupancy is then about 10-3, corresponding

to ~0.5 GeV on the electromagnetic (em) energy scale. The gain Apixel

is measured with low intensity LED light and used for non-linearity correction.

The energy per cell in units of MIPs is then obtained from the formula

E [MIP] = A/AMIP ∗ F

(Npixel) with Npixel = A/Apixel

where A is amplitude measured in ADC counts. The non-linearity

correction F depends only on the amplitude in units of pixels and is 1

for small amplitudes (all scale factors are absorbed in the MIP calibration

factor). The function F is the inverse of the normalized response

function and can be approximated as F= −

N/Npixel * log (1−Npixel/N)

for a total of N active pixels on the MGPD. In practice Fis obtained

from the test bench measurements. The conversion from MIPs to deposited

energy depends on the incident particle type and is taken from simulations or

using the known beam energy as reference. MIP and pixel scale are subject to

temperature variations of a few percent per Kelvin. The redundant monitoring

system offers various possibilities for correcting these effects, using gain,

LED reference signals or direct temperature measurement.

The scintillator based hadron calorimeter relies on the use of novel Multi-Pixel

Geiger mode silicon Photo-Detectors (MGPDs). The MGPD (often called Silicon Photomultiplier

- SiPM)

is a pixilated avalanche photo-diode operated in limited Geiger mode (see figure on the

left). The detector surface of lxl mm² is divided into 1156 pixels. We gained

experience with this photodetector building small test calorimeter MiniCal with

about 100 MGPD channels [see MiniCal].

The scintillator based hadron calorimeter relies on the use of novel Multi-Pixel

Geiger mode silicon Photo-Detectors (MGPDs). The MGPD (often called Silicon Photomultiplier

- SiPM)

is a pixilated avalanche photo-diode operated in limited Geiger mode (see figure on the

left). The detector surface of lxl mm² is divided into 1156 pixels. We gained

experience with this photodetector building small test calorimeter MiniCal with

about 100 MGPD channels [see MiniCal].