ECAL

CALICE ECal is a novel type of

electromagnetic calorimeter employing tungsten as a radiator and

square silicon diode pixels called pads as sensors. It is made of 30

sandwich layers of alternating tungsten layers and PCBs. The

mechanical structure is made of tungsten wrapped in a carbon fiber.

Almost each layer consists of 3 by 3 matrix of silicon wafers, each

wafer has 6 by 6 square Si pads. The very front end electronics is

located outside of the active area, mounted on a PCB. CALICE ECal

prototype has more than 9 000 active sensor elements in total. Signals

from the PCBs are read out via cables to the VME64 crate which

provides digitization and readout.

[obrazok TB setupu]

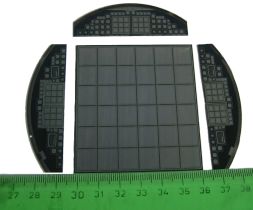

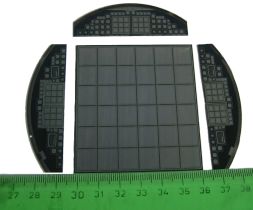

Silicon Wafers

CALICE ECal employs silicon

diodes for detection of passage and measurement of the deposited

energy of passing charged particles. Sensor is manufactured on the 4

inch wafer with high resistivity, about 5 kΩcm. Silicon wafer is 525

μm thick.

CALICE ECal employs silicon

diodes for detection of passage and measurement of the deposited

energy of passing charged particles. Sensor is manufactured on the 4

inch wafer with high resistivity, about 5 kΩcm. Silicon wafer is 525

μm thick.

One wafer is a matrix of a 6

by 6 pads. One pad is 10x10 mm² large.

Wafer is slightly larger than 60 mm because of the included 1 mm guard

rings which safeguard surface currents and make electric field in the

active volume homogeneous on the border. About half of the wafers for

the CALICE ECal prototype was made by the On Semiconductor company in

Roznov in Czech republic.

Detection

Pads are p-n junction diodes

operated at reverse bias. This forms a sensitive region depleted of

mobile charge carriers and sets up an electric field that sweeps

charge liberated by a passage of radiation to the electrodes. High-resistivity

silicon is used for detector fabrication and therefore it is possible

to fully deplete the volume at voltages of about 150 to 200 V. When an

ionizing particle passes through, energy loss of just 3.6eV creates an

electron-hole pair. This is an order of magnitude less than energy

needed to produce electron-ion pair in gasses or about two orders of

magnitude less than energy necessary for production of a single photon

in scintillation counter. Passage of a minimum ionizing particle

through the fully depleted volume of the CALICE ECal prototype pad

should create about 42000 electron hole pairs. The read-out signal is

processed in the front end chips and converted to the digital form and

finally stored after a processing chain on the grid.

Mechanics

ECal prototype consists of 3

stacks, each has 10 layers of an alternating structure of tungsten and

silicon. Each stack has tungsten of different thickness: 1.4mm or 0.4

X0 per layer per for the stack, 2.8mm or 0.8 X0

for the layers in the second stack and 4.2mm or 1.2X0 for

the layers in the rear stack. This selection should guarantee a good

resolution at low energy due to the thinner tungsten at the front and

it should contain the electromagnetic showers well because of the

thick tungsten layers at the rear.

Silicon pads are mounted to

the PCBs by a mean of conductive glue. The signal is read out from a

single PCB using the FLC_PHY3 front end chips on the PCB which contain

input charge-sensitive preamplifier, signal shaper and a 18:1

multiplexer. Output is analog. The silicon wafers on each side of the

slab are staggered in the horizontal direction for the reasons of

avoiding alignment of guard rings.

[obrazok stacku]

CALICE ECal employs silicon

diodes for detection of passage and measurement of the deposited

energy of passing charged particles. Sensor is manufactured on the 4

inch wafer with high resistivity, about 5 kΩcm. Silicon wafer is 525

μm thick.

CALICE ECal employs silicon

diodes for detection of passage and measurement of the deposited

energy of passing charged particles. Sensor is manufactured on the 4

inch wafer with high resistivity, about 5 kΩcm. Silicon wafer is 525

μm thick.